Structural safety verification is a critical process for electric and hybrid vehicles, ensuring their structures can withstand diverse stresses and impacts. Advanced testing methods mimic real-world conditions to identify weaknesses, focusing on chassis, battery compartments, and suspension systems. The ultimate goal is to deliver reliable repair services, meet stringent safety standards, and enhance vehicle safety daily. For luxury brands like Mercedes-Benz, adhering to these standards is paramount to maintaining passenger security. Regular auto maintenance, including prompt damage repair, also plays a vital role in preserving structural integrity.

“In the rapidly evolving landscape of electric and hybrid vehicles, ensuring structural safety is paramount. This article delves into the critical process of Structural Safety Verification, exploring its definition, significance, and key considerations for maintaining integrity in these advanced automobiles. We break down the step-by-step procedures, tools, and regulatory standards guiding verification. Furthermore, we examine challenges, including material selection complexities, and highlight future trends driven by simulation advancements and AI/ML applications, shaping a safer automotive horizon.”

- Understanding Structural Safety Verification

- – Definition and significance in electric and hybrid vehicles

- – Key considerations for structural integrity

Understanding Structural Safety Verification

Structural safety verification is a critical process that ensures the integrity and resilience of electric and hybrid vehicles’ structures. It involves a comprehensive evaluation to guarantee that the car’s body can withstand various stresses and impacts, protecting both its occupants and the environment. This procedure is essential in identifying potential weaknesses or vulnerabilities in the vehicle’s design and construction, especially with advancements in material science and manufacturing techniques.

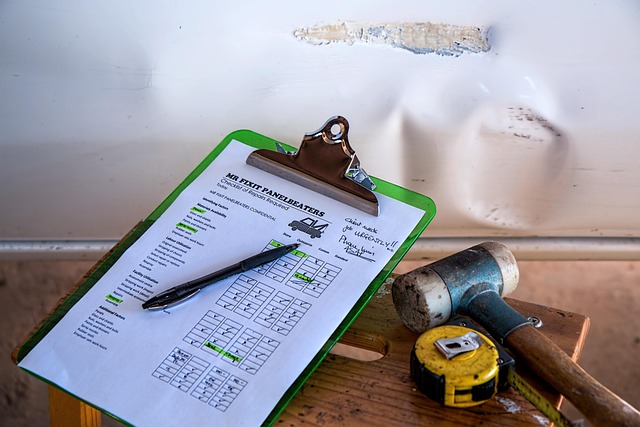

Automotive professionals employ advanced testing methods and simulations to mimic real-world scenarios, such as accidents or extreme weather conditions. By doing so, they can assess the structural safety of components like the car body shop repairs, ensuring that paintless dent repair techniques are effective and reliable. The ultimate goal is to deliver top-notch auto repair services while adhering to stringent safety standards, making electric and hybrid vehicles safer for everyday use.

– Definition and significance in electric and hybrid vehicles

Structural safety verification is a critical process in the automotive industry, especially for electric and hybrid vehicles. These innovative powertrains introduce unique challenges that require rigorous testing to ensure passenger safety and vehicle integrity. In the context of electric and hybrid cars, structural safety verification goes beyond traditional methods, focusing on the integration of high-voltage systems, lightweight materials, and advanced battery packs. It involves meticulous examination of components like chassis, body panels, and frames to guarantee they can withstand various driving conditions and potential accidents without compromising the vehicle’s overall safety.

This verification process is essential in preventing catastrophic car damage repair scenarios, which could lead to severe injuries or even fatalities. For premium brands like Mercedes-Benz, adhering to stringent structural safety standards is paramount. By implementing comprehensive testing protocols, manufacturers can identify weak points, enhance crashworthiness, and minimize the need for extensive fender repair or other costly damage repairs post-accidents. Through this meticulous approach, electric and hybrid vehicles can offer the same level of passenger security as their conventional counterparts.

– Key considerations for structural integrity

When it comes to electric and hybrid vehicles, ensuring structural safety verification is paramount. Key considerations for maintaining structural integrity include rigorous testing protocols that mimic real-world driving conditions, focusing on critical areas like chassis, battery compartments, and suspension systems. These tests should evaluate the vehicle’s ability to withstand various forces, such as impact, rollovers, and extreme weather conditions, which are essential elements in structural safety verification.

Moreover, regular auto maintenance plays a crucial role in preserving the structural integrity of these vehicles. Proper care, including timely car damage repair and inspection, helps identify potential issues early on. This proactive approach not only ensures optimal performance but also prevents catastrophic failures by addressing auto bodywork concerns promptly, thereby enhancing overall vehicle safety.

Structural safety verification is an indispensable process in ensuring the integrity and reliability of electric and hybrid vehicles. By meticulously assessing the structural components, designers can identify potential risks and weaknesses, leading to safer and more robust vehicle designs. This comprehensive procedure, which encompasses rigorous testing and simulation, plays a pivotal role in building confidence among consumers and regulatory bodies alike. Implementing these verification methods is crucial for the continued development of advanced transportation systems, pushing the boundaries of electric mobility while maintaining unparalleled safety standards.