Documentation of Structural Safety Verification: Transparent Repair Processes

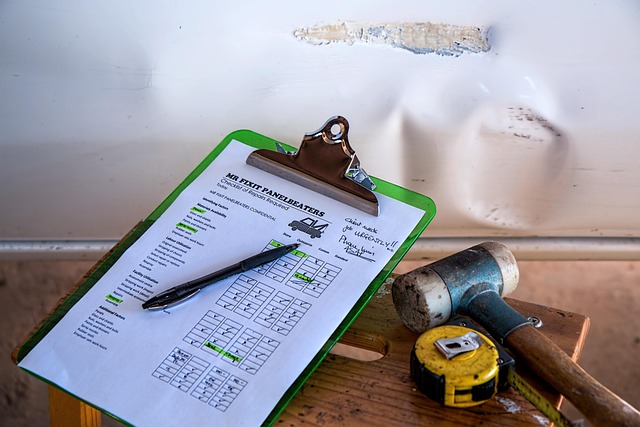

Structural Safety Verification (SSV) is a crucial process in auto body restoration, ensuring vehicle…….

Structural safety verification is a critical process that ensures the integrity and stability of buildings, bridges, and other infrastructure. It involves meticulous analysis, testing, and certification to guarantee that structures can withstand various loads, environmental conditions, and potential failures, thereby safeguarding lives and property. This article aims to provide an in-depth exploration of structural safety verification, its global impact, technological innovations, regulatory frameworks, and its pivotal role in shaping the built environment. By delving into these aspects, we will uncover the significance of this process and its influence on various sectors.

Structural safety verification is a comprehensive evaluation method employed to assess and certify the structural integrity of buildings and structures. It involves analyzing design calculations, conducting inspections, and employing simulation techniques to ensure that the structure meets established safety standards and codes. The core components include:

Design Analysis: Engineers perform detailed calculations to verify that the structure can resist loads such as wind, earthquakes, snow, and dead weight. This phase includes material property analysis, load combination, and structural modeling.

Code Compliance: Adherence to local building codes and regulations is paramount. These codes dictate minimum safety standards for construction, including permitted load capacities, building dimensions, and material specifications.

Inspection and Testing: Physical inspections are conducted to examine the structure’s quality, workmanship, and adherence to design plans. Non-destructive testing (NDT) methods, such as ultrasound and magnetic particle inspection, are employed to assess material integrity without causing damage.

Simulation and Modeling: Advanced computer simulations are used to model structural behavior under various conditions. This enables engineers to predict potential failure points and refine designs for enhanced safety.

The concept of structural safety verification has evolved over centuries, driven by the need to construct safer buildings after significant disasters. The early 19th century saw the introduction of building codes in response to devastating fires, while the 20th century brought about advancements in material science and engineering, leading to more sophisticated design methods.

The post-World War II era marked a turning point with the emergence of computer-aided design (CAD) software, which revolutionized structural analysis. Today, structural safety verification benefits from advanced simulation tools, machine learning for predictive analytics, and the integration of Internet of Things (IoT) sensors for real-time monitoring.

Structural safety verification is a universally recognized practice, albeit with variations in implementation across countries. The influence of global standards, such as those set by the International Organization for Standardization (ISO), has fostered consistency in structural design and safety protocols. Many nations have adopted or adapted these standards to suit their local contexts.

North America: Strict building codes and a robust construction industry characterize this region. Advanced engineering software and digital twin technology are widely adopted, ensuring efficient and safe structural designs.

Europe: The European Union’s (EU) comprehensive framework of building regulations and standards sets a high bar for structural safety. The use of modular construction methods and advanced composite materials is gaining traction to enhance both safety and sustainability.

Asia Pacific: Rapid urbanization drives the need for robust structural safety verification in this region. China, for instance, has implemented stringent safety measures following major disasters, leading to innovative design solutions. Japan’s focus on seismic resistance has resulted in world-class engineering practices.

Middle East and Africa: Growing cities in these regions require careful planning and construction monitoring. The integration of smart city technologies and digital safety verification tools is gaining momentum to address infrastructure challenges.

The structural safety verification market is influenced by various economic factors, including:

Construction Industry Growth: Rising global construction spending drives the demand for advanced structural safety services. Developing economies contribute significantly to this growth.

Regulatory Compliance: Stringent building codes and safety regulations necessitate increased investment in safety verification, particularly in regions with historically lax standards.

Technological Advancements: The adoption of new technologies, such as AI-driven analysis and digital modeling, can reduce costs and expedite project timelines, making it a competitive market.

Public Sector Spending: Governments invest heavily in infrastructure development, including safety verification for public buildings, bridges, and transportation networks.

Private Sector Engagement: The private construction sector contributes significantly to the market through commercial building projects, residential developments, and industrial facilities.

International Collaboration: Cross-border construction projects drive demand for specialized safety verification services, fostering international collaboration and knowledge exchange.

The digital revolution has transformed structural safety verification through:

Computer-Aided Design (CAD): CAD software enables precise modeling and analysis, streamlining the design process and improving accuracy.

Building Information Modeling (BIM): BIM provides a comprehensive digital representation of buildings, allowing for better coordination between design disciplines and enhanced safety analysis.

Advanced Simulation Tools: Finite Element Analysis (FEA) and other simulation techniques predict structural behavior under various scenarios, helping engineers identify potential issues early in the design phase.

Artificial Intelligence (AI): AI algorithms can analyze vast amounts of data to identify patterns and predict structural failures, enhancing safety and efficiency.

Internet of Things (IoT): IoT sensors integrated into structures provide real-time monitoring, enabling proactive maintenance and improved safety management.

Digital Twins: Creating digital replicas of physical structures allows for virtual testing and simulation, reducing the need for expensive physical prototypes.

Structural safety verification is guided by a web of policies and regulations that vary across jurisdictions:

Building Codes: Local building codes dictate minimum design requirements, permitted construction methods, and material standards to ensure structural integrity.

Safety Standards: Organizations like ISO and ASTM International develop voluntary and mandatory standards for various aspects of structural safety, including materials, testing methods, and design practices.

Legislative Requirements: Governments enact laws mandating safety verification for specific types of structures, such as high-rise buildings, bridges, and critical infrastructure.

Ensuring Safety Compliance: Regulatory frameworks force engineers and builders to adhere to strict safety standards, minimizing the risk of structural failures that could lead to catastrophic events.

Promoting Innovation: While regulations ensure safety, they also stimulate innovation by encouraging the adoption of advanced technologies and design methodologies.

Risk Management: Regulations help manage risks by defining acceptable levels of risk and dictating measures to mitigate potential hazards.

Despite its critical role, structural safety verification faces several challenges:

Complex Structural Designs: Modern buildings, with their intricate designs and varied materials, pose complex analysis and testing challenges, requiring advanced tools and expertise.

Data Quality and Consistency: Ensuring the accuracy and consistency of data from various sources is crucial for reliable verification, especially in large-scale projects.

Cost and Time Constraints: Strict safety requirements can increase project costs and timelines, especially when extensive testing and simulations are required.

Standardized Digital Protocols: Developing standardized digital protocols and platforms can facilitate data exchange and interoperability between different software tools, ensuring consistency.

Advanced Material Testing: Investing in advanced material testing facilities and methodologies enables more efficient and accurate characterization of building materials.

Integrated Safety Platforms: Creating integrated software solutions that combine design, analysis, and simulation tools can streamline the verification process and reduce costs.

This iconic skyscraper stands as a testament to structural safety verification excellence. Engineers utilized advanced seismic analysis techniques and composite material designs to withstand potent earthquakes in the region. Digital simulations predicted optimal structural configurations, ensuring the tower’s stability and resilience.

Initially plagued by concerns over vibration-induced stress, this bridge was subject to extensive safety verification tests. By employing advanced dynamic analysis and modeling, engineers addressed the issues, demonstrating the importance of thorough verification in high-profile infrastructure projects.

As the world’s tallest building, the Burj Khalifa required meticulous structural safety verification. Engineers faced challenges due to extreme height and diverse climatic conditions. They employed detailed wind load analyses, dynamic simulations, and advanced construction monitoring systems to ensure its safety and stability.

Sustainable Construction: As green building standards evolve, structural safety verification will need to incorporate environmental considerations, such as the use of sustainable materials and energy-efficient designs.

Off-Site Construction: Pre-fabricated and modular construction methods are gaining traction, requiring specialized safety verification processes to ensure quality control during manufacturing and assembly.

Smart Cities: The integration of structural safety verification with smart city technologies will enable real-time monitoring and adaptive design, enhancing urban resilience.

Predictive Analytics: AI-driven predictive models can anticipate structural issues before they occur, allowing for proactive maintenance and reduced downtime.

Digital Twin Evolution: Advanced digital twins will incorporate more realistic simulation capabilities, enabling virtual testing of various scenarios and optimization of design solutions.

Structural safety verification is a multifaceted discipline that plays a pivotal role in shaping the built environment. From historical evolution to global adoption, this process ensures the resilience and longevity of structures worldwide. Technological advancements, regulatory frameworks, and successful case studies collectively underscore its importance.

Looking ahead, the future of structural safety verification promises enhanced digital capabilities, sustainable construction practices, and smarter cities. As the demand for infrastructure continues to grow, efficient and safe structural designs will remain a top priority, ensuring the well-being of occupants and communities worldwide.

Q: How does structural safety verification differ from traditional building inspection?

A: While both ensure structure integrity, traditional inspections often focus on visual assessments and code compliance, whereas structural safety verification involves comprehensive analysis, testing, and simulation to predict performance under various loads and conditions.

Q: Can AI truly replace human engineers in structural safety verification?

A: AI assists in analysis and pattern recognition but lacks human creativity and contextual understanding. It is a powerful tool for enhancing efficiency and accuracy, but human expertise remains crucial for complex design challenges and regulatory compliance.

Q: What are the benefits of using BIM in structural safety verification?

A: BIM provides a centralized digital model, enabling better coordination between disciplines, improved visualization, and efficient clash detection. It streamlines the verification process by allowing for virtual testing and simulation, reducing physical prototypes and saving time.

Q: How do regional differences impact structural safety standards?

A: Local conditions, climate, and historical construction practices influence regional variations in building codes and safety standards. These adaptations ensure that structures meet specific challenges while maintaining global safety benchmarks.

Structural Safety Verification (SSV) is a crucial process in auto body restoration, ensuring vehicle…….

The regulatory environment for structural safety verification in automotive and construction sectors…….

Structural Safety Verification is a game-changer for auto body shops, prioritizing meticulous inspec…….

Structural Safety Verification (SSV) is a rigorous process utilizing advanced technologies like CAD,…….

Structural safety verification is a vital process ensuring road infrastructure maintains integrity a…….

Understanding the frame and unibody structure is essential for ensuring vehicle safety during collis…….