The construction industry has embraced digital measuring tools, drastically transforming structural safety verification. Traditional manual methods have been superseded by advanced technologies like 3D scanners and drone mapping, enabling precise digital modeling of buildings. This shift has led to more accurate structural assessments and improved building quality, while also facilitating proactive maintenance. Similar advancements in auto dent repair using digital measurement technology have reduced turnaround times and increased customer satisfaction by swiftly identifying damage and weak spots through precise data capture, enhancing overall structural safety verification.

In today’s digital era, the construction industry is undergoing a transformation with the advent of advanced measuring tools. This article explores how digital technology is revolutionizing structural safety verification, enhancing accuracy and efficiency in ways traditional methods can’t match. We trace the evolution of digital measurement tools, highlighting their benefits and impact on construction practices. Furthermore, we delve into successful case studies, navigate potential challenges, and discuss emerging trends such as AI and BIM that are poised to shape the future of structural safety verification.

- The Evolution of Digital Measuring Tools in Construction

- – A brief history of digital measurement technology

- – Benefits over traditional methods

The Evolution of Digital Measuring Tools in Construction

The construction industry has witnessed a remarkable transformation with the advent of digital measuring tools, revolutionizing how structural safety verification is conducted. What was once a labor-intensive process relying on manual measurements and traditional techniques is now streamlined and accurate thanks to technological advancements. These modern tools offer precision and efficiency, ensuring every aspect of a building’s structure is meticulously measured and analyzed.

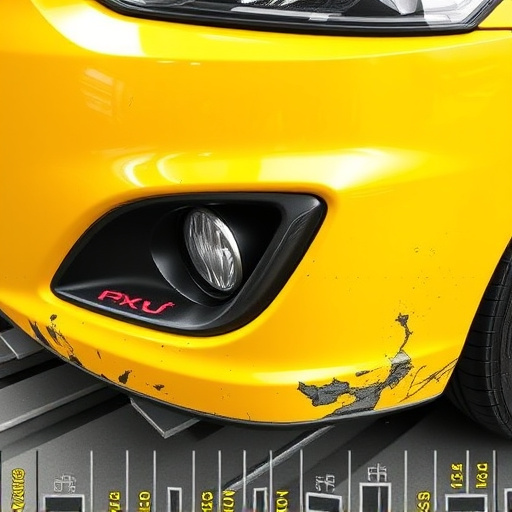

Digital measuring devices have evolved from simple laser distance meters to sophisticated 3D scanners and drone-based mapping systems. For example, construction professionals can now use advanced software to create detailed digital models of structures, enabling them to virtually inspect every angle and corner. This shift from traditional bumper repair methods (like manual measuring tapes) in construction has significantly improved the structural safety verification process, leading to more accurate assessments and better overall building quality. Moreover, these tools facilitate regular maintenance and help identify potential issues early on, mirroring how timely tire services can prevent larger problems in vehicles.

– A brief history of digital measurement technology

Digital measurement technology has evolved significantly over the years, transforming industries and processes worldwide, including structural safety verification. The journey began with rudimentary analog tools like measuring tapes and calipers, which laid the foundation for precise manual measurements. As technological advancements took hold, digital innovations such as laser distance meters and 3D scanning emerged in the late 20th century. These early adopters introduced new levels of accuracy and efficiency to various sectors, setting the stage for more sophisticated applications.

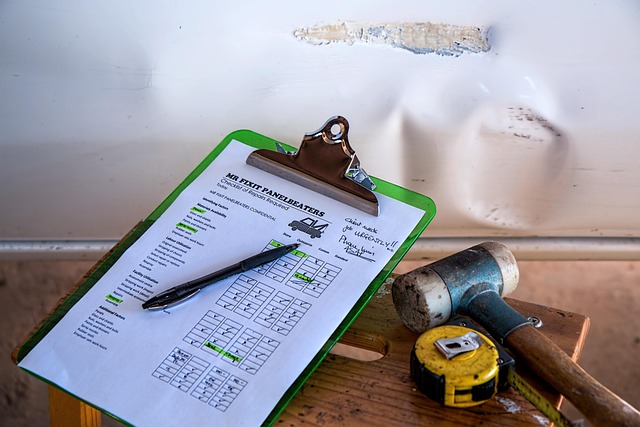

Today, digital measuring tools have become indispensable assets in ensuring structural safety verification across diverse fields, from construction to automotive industries (including car scratch repair and auto body shops). Advanced technologies like photogrammetry and computer-aided measurement systems offer unparalleled precision, enabling professionals to detect even minute imperfections that could impact overall safety. This evolution has not only enhanced the accuracy of structural assessments but also streamlined workflows in auto dent repair processes, contributing to faster turnaround times and improved customer satisfaction.

– Benefits over traditional methods

In today’s digital era, the advent of advanced measuring tools has revolutionized structural safety verification, offering significant advantages over traditional methods. Manual inspections and measurements, once the standard, are time-consuming, prone to human error, and may overlook critical defects. Digital tools, on the other hand, provide an accurate, efficient, and comprehensive solution. They enable engineers and mechanics to swiftly capture precise data, ensuring no detail is missed during the verification process.

These innovations are especially beneficial in industries like vehicle body repair, where structural integrity is paramount after accidents (auto collision repair or vehicle collision repair). Digital measuring tools can quickly assess damage, pinpoint weak spots, and generate detailed reports, facilitating more effective repairs. This enhances not just the accuracy of structural safety verification but also streamlines the overall restoration process.

Digital measuring tools have revolutionized structural safety verification, offering unparalleled accuracy and efficiency compared to traditional methods. Their evolution, driven by technological advancements, has streamlined construction processes, ensuring safer buildings and reduced human error. As these tools continue to improve, the industry can look forward to even more precise and timely structural assessments, ultimately enhancing overall project quality and safety standards.